WarpAstron WarpDrive WD-17 Harmonic Drive Mount with Servo Direct Drive

Available from UK stock for immediate dispatch. Free shipping to UK mainland.

The WD-17 is the first harmonic drive mount based on Servo Direct Drive technology. It has only a single stage reducer - backlash-less strain wave reducer, and eliminate the transmission/assembly error from belt/planetary gear solution. That’s why we called it “harmonic drive” mount, providing high precision guiding performance to you.

RA axis using Type 17 SWR which providing same load capacity like most of harmonic drive mounts at the same time. It only weighs 3.8kg including the clamping that supports both Vixen & Losmandy-style dovetails.

The Alignment Base (wedge) can be smoothly fine adjusted with CNC machined fine tooth screw and gap control design, which makes it much easier for polar alignment.

How WARPDRIVE mount different from others?

WarpAstron’s WD-17S and WD-20 use servo with high precision encoder as input of stain wave reducer(harmonic drive), servo directly connected with reducer via a shaft for both DEC & RA.

Most harmonic drive mount will use additional reducer like timing belt or planetary gear before strain wave reducer. Thought very few mount will also use direct drive, its motor still be stepper which have issues on loss of torque when operating at high micro-step mode or imprecise positioning.

No additional timing belt/planetary gear used in our mount. The mount’s guiding correction accuracy and performance benifit a lot with this extreme low bachlash drive solution. No need of maintenance for belt which may be impact by aging or low temperature.

What's the difference between direct drive, belt and planetary?

Planetary gear/Timing belt

We all know that planetary has large backlash due to its structure, even 3~5 arcmins for high precision planetary which already much expensive.

Though timing belt has no backlash like planetary gear, belt require strictly adjustment for its tension – too large tension may cause overload, while less tension will result in shaping, lead to untimely response during guiding correction. What’s more, the tension will be changed with belt aging and temperature. It require maintenance and adjustment to stay in good tension level for ideal mount performance.

The strain wave reducer has much advantage on its low backlash(<10″), which even been called “zero” backlash. but mount’s guiding accuracy based on system transmission error, not only SWR’s periodic error – the transmission/assembly error introduced by additional belt/planetary gear could be several times greater than SWR’s PE.

Direct Drive

WARPDRIVE Mounts’ servo motor directly connected to input of strain wave reducer via a simple shaft. No backlash/transmission error existed between servo and SWR, with the advantage of high transmission efficiency.

And we use special designed servo with high precision encoder instead of stepper for both axises. Servo can provide constanly torque in whole RPM range, without torque loss issue like stepper. Our servos based on BLDC motor and have no reducer struction inside it – Direct and strong power input for mount. High precision encoder support the motor response quickly and precisely to guide correction, and less sensitive to load change.

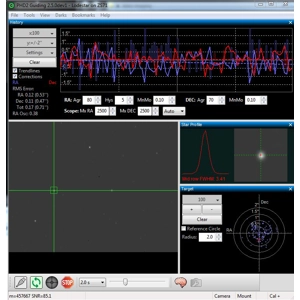

How about the guide performance of WARPDRIVE mount?

Based on feedbacks from our users, WARPDRIVE mount benifit a lot based on its servo direct drive – precise and responsive to guide correction, the average guiding performance can easily get to 0.3~0.5″ RMS. Depending on guiding system sampling level(Typical 1 second exposure).

Detail refer to PHD2 log examples on our website, provided by our users.

What's the maximum load capacity of your mount? Can it handle my XX scope?

Mount’s load capacity depend on BOTH load weight and moment the force. It’s more precision to talk about torque not simple weight. Torque(Nm) = Load Weight(kg) * Moment (m). Below for GEM mode:

WD-20 can handle 50NM without counterweight, equal to 20kg load at the 25cm from RA axis.

WD-17S can handle 38NM without counterweight, equal to 15kg load at the 20cm from RA axis.

Please noticed that even your load with in the capacity of mount, you still need to use properly pier/tripod to improve stability of whole system, and also use couterweight properly to balance the tripod to prevent it falling or other safety issue. Good tracking and guiding performance rely on both mounts and tripod/pier.

Does the mount have Alt/Az mode?

All our mounts support both GEM and Alt/Az mode. Altitude adjustment range from 0~90°. You can switch the mode via Hand controller.

What's the lowest temperature that mount can operate properly?

Our mount can work well lower to -25°C~30 °C.

Direct drive is much reliable in extreme low temperature. No need to worry time belt maybe shaping even torn in low temperature.

Both WD-17S and WD-20 have special heating design by brake. Brake device can provide additional heating for improve operationg condition for SWR. If user require extreme low temperature below -25°C, please ask our Customer Support for firmware update.

What astrography software can I use for WARPDRIVE mounts?

Thanks to OnStep Community, our mounts can support most frequently used software basedon NINA or INDI driver, such as NINA, Kstars, or astro computer like Stellarmate, ASIAIR.

GBP

GBP AED

AED AFN

AFN ALL

ALL AMD

AMD ANG

ANG AOA

AOA ARS

ARS AUD

AUD AWG

AWG AZN

AZN BAM

BAM BBD

BBD BDT

BDT BGN

BGN BHD

BHD BIF

BIF BMD

BMD BND

BND BOB

BOB BRL

BRL BSD

BSD BTN

BTN BWP

BWP BYN

BYN BZD

BZD CAD

CAD CDF

CDF CHF

CHF CLF

CLF CLP

CLP CNH

CNH CNY

CNY COP

COP CRC

CRC CUC

CUC CUP

CUP CVE

CVE CZK

CZK DJF

DJF DKK

DKK DOP

DOP DZD

DZD EGP

EGP ERN

ERN ETB

ETB EUR

EUR FJD

FJD FKP

FKP GEL

GEL GGP

GGP GHS

GHS GIP

GIP GMD

GMD GNF

GNF GTQ

GTQ GYD

GYD HKD

HKD HNL

HNL HRK

HRK HTG

HTG HUF

HUF IDR

IDR ILS

ILS IMP

IMP INR

INR IQD

IQD IRR

IRR ISK

ISK JEP

JEP JMD

JMD JOD

JOD JPY

JPY KES

KES KGS

KGS KHR

KHR KMF

KMF KPW

KPW KRW

KRW KWD

KWD KYD

KYD KZT

KZT LAK

LAK LBP

LBP LKR

LKR LRD

LRD LSL

LSL LYD

LYD MAD

MAD MDL

MDL MGA

MGA MKD

MKD MMK

MMK MNT

MNT MOP

MOP MRU

MRU MUR

MUR MVR

MVR MWK

MWK MXN

MXN MYR

MYR MZN

MZN NAD

NAD NGN

NGN NIO

NIO NOK

NOK NPR

NPR NZD

NZD OMR

OMR PAB

PAB PEN

PEN PGK

PGK PHP

PHP PKR

PKR PLN

PLN PYG

PYG QAR

QAR RON

RON RSD

RSD RUB

RUB RWF

RWF SAR

SAR SBD

SBD SCR

SCR SDG

SDG SEK

SEK SGD

SGD SHP

SHP SLE

SLE SLL

SLL SOS

SOS SRD

SRD SSP

SSP STD

STD STN

STN SVC

SVC SYP

SYP SZL

SZL THB

THB TJS

TJS TMT

TMT TND

TND TOP

TOP TRY

TRY TTD

TTD TWD

TWD TZS

TZS UAH

UAH UGX

UGX USD

USD UYU

UYU UZS

UZS VES

VES VND

VND VUV

VUV WST

WST XAF

XAF XCD

XCD XCG

XCG XOF

XOF XPF

XPF YER

YER ZAR

ZAR ZMW

ZMW ZWG

ZWG ZWL

ZWL UK English

UK English Swedish

Swedish Spanish

Spanish Norwegian

Norwegian Dutch

Dutch German

German Arabic

Arabic